The main advantages of choosing a reputable Aluminum Casting Company for your needs

The Significance of Light Weight Aluminum Casting in High-Quality Production Techniques

Light weight aluminum casting has actually become a keystone in premium manufacturing methods. Its light-weight properties and remarkable stamina make it a preferred choice for different sectors. Suppliers profit from its design versatility and marginal waste generation. As the need for innovative products grows, recognizing the subtleties of light weight aluminum casting becomes important. This expedition reveals not just its advantages yet likewise the progressing innovations that shape its future in production. What lies in advance for this ingenious procedure?

The Benefits of Aluminum Spreading

Numerous casting methods exist, light weight aluminum casting stands out due to its various benefits. Among the main advantages is its lightweight nature, which substantially reduces transportation prices and power usage in applications. Light weight aluminum also displays excellent deterioration resistance, making it suitable for durable components in diverse settings. The spreading procedure allows for detailed styles, allowing producers to create intricate shapes with high accuracy and very little waste. In addition, light weight aluminum has superior thermal and electric conductivity, making it appropriate for a variety of commercial applications. The high strength-to-weight proportion boosts the architectural stability of cast items, offering durability without the included mass. Aluminum casting can be adapted to numerous strategies, such as sand casting or die spreading, which expands its applicability throughout sectors. On the whole, these benefits setting light weight aluminum casting as a recommended selection in modern manufacturing, adding to performance and sustainability.

Key Applications of Aluminum Casting

Aluminum spreading discovers considerable applications throughout different sectors as a result of its advantageous properties. In the automobile market, it is widely used for manufacturing engine blocks, transmission situations, and wheels, promoting light-weight designs that improve gas effectiveness. The aerospace industry likewise takes advantage of aluminum casting, where elements such as real estates and braces are created to meet rigorous weight and strength requirements.

Furthermore, the electrical field uses light weight aluminum casting for producing housings and heat sinks, which are essential for reliable thermal monitoring in electronic tools. Aluminum Foundry. The construction industry uses aluminum castings for building components, window frameworks, and fixtures, contributing to both looks and toughness

Lastly, the consumer goods industry includes light weight aluminum spreading in things like cooking equipment and showing off devices, leveraging the material's toughness and rust resistance. In general, the convenience of aluminum spreading makes it a vital procedure in conference varied production needs throughout numerous fields.

The Refine of Light Weight Aluminum Casting

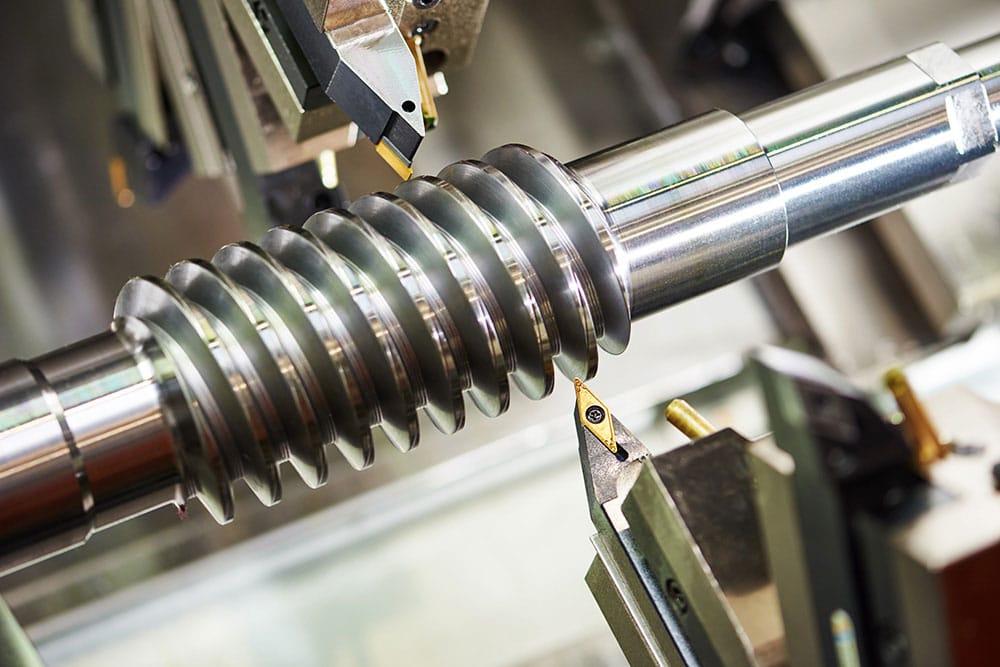

Casting aluminum involves a number of distinct actions that transform resources into ended up elements. The procedure begins with melting aluminum in a heating system, reaching temperatures around 660 levels Celsius. As soon as thawed, the fluid aluminum is poured right into a mold and mildew, which takes the shape of the desired element. Various mold and mildew kinds, consisting of sand, long-term, and investment mold and mildews, are used depending on the application.

After putting, the aluminum cools and strengthens, forming a harsh casting. This spreading undergoes a series of ending up processes, such as machining, to accomplish accurate measurements and surface area quality. Quality assurance procedures are carried out throughout to assure the honesty and stamina of the final product. When all procedures are complete, the finished aluminum elements await numerous applications, showcasing the flexibility and effectiveness of aluminum spreading in manufacturing techniques. Each action is crucial in attaining top quality results, making this procedure necessary in making markets.

Innovations in Light Weight Aluminum Spreading Modern Technology

Recent improvements in light weight aluminum spreading modern technology have actually transformed manufacturing processes significantly. Innovations such as advanced spreading approaches, integration of clever production, and sustainability techniques are improving the market. These growths not only boost performance however likewise address ecological problems, leading the way for an extra lasting future in light weight aluminum casting.

Advanced Spreading Methods

As makers seek higher efficiency and sustainability in manufacturing, innovative improvements in light weight aluminum casting innovation have emerged to satisfy these demands. Advanced casting methods, such as die casting, financial investment spreading, and sand spreading, have actually been fine-tuned to improve precision and minimize waste. Pass away casting enables faster production prices and tighter resistances, making it excellent for high-volume items. Investment casting, understood for its capability to produce complex geometries, enables intricate layouts with superior surface finishes. Sand spreading stays preferred for its versatility and cost-effectiveness, particularly in low-volume applications. These methods not only enhance the quality of light weight aluminum components but also add to lowered energy consumption, lining up with market objectives for lasting techniques in producing processes.

Smart Production Combination

Just how can smart manufacturing integration change aluminum spreading innovation? By including innovative modern technologies such as the Net of Points (IoT), artificial intelligence (AI), and information analytics, smart manufacturing enhances performance and accuracy in aluminum casting processes. Real-time surveillance of equipment and assembly line allows for prompt modifications, lowering waste and downtime. Anticipating maintenance powered by AI minimizes equipment failures, making certain constant high quality. Additionally, information analytics can maximize casting parameters and layouts, bring about much better product usage and lowered cycle times. These technologies promote smooth interaction between drivers and machines, cultivating an extra active production setting. On the whole, wise production integration significantly boosts the capabilities of light weight aluminum casting, promoting greater top quality outputs and even more responsive manufacturing techniques.

Sustainability Innovations

While the aluminum spreading market faces raising stress to take on sustainable practices, developments are arising that substantially lower its ecological influence. Advanced recycling methods currently allow producers to use as much as 95% recycled aluminum, greatly reducing energy intake and waste generation. In addition, the combination of low-emission modern technologies, such as electric melting furnaces, decreases greenhouse gas discharges associated with traditional casting approaches. Furthermore, the advancement of green finishings and binders changes hazardous chemicals, improving office safety and security and reducing environmental contamination. These innovations not only align with worldwide sustainability objectives but likewise improve the total efficiency and high quality of light weight aluminum products. As the industry develops, these advancements will play a vital duty in cultivating a more lasting future for light weight aluminum casting.

Contrasting Light Weight Aluminum Casting With Various Other Approaches

In comparing light weight aluminum casting with other making approaches, a number of crucial elements arise. Price effectiveness, stamina and resilience, and style versatility serve as vital metrics for examination (Aluminum Foundry). Analyzing these elements can give understandings into the advantages and constraints of aluminum casting in numerous production contexts

Expense Efficiency Evaluation

Price effectiveness stays a critical consideration in making procedures, especially when reviewing aluminum spreading versus alternate techniques. Light weight aluminum spreading frequently provides a lower initial financial investment compared to methods such as steel building or machining, which call for even more intricate and pricey devices. Furthermore, light weight aluminum's light-weight nature can minimize transportation costs and energy consumption throughout manufacturing. The ability to create complicated forms with marginal waste further boosts its cost-effectiveness, as less material is discarded throughout the production procedure. Light weight aluminum casting normally enables for quicker production cycles, leading to decreased labor costs and faster turn-around times. To summarize, when comparing price effectiveness, aluminum casting frequently arises as a desirable option, supplying makers monetary benefits alongside top quality result.

Strength and Longevity

Strength and durability are crucial elements when assessing production approaches, specifically in the context of aluminum casting. Contrasted to various other methods such as plastic injection molding and steel manufacture, aluminum spreading supplies distinct advantages. The integral buildings of aluminum, integrated with the casting process, lead to light-weight yet robust parts that can stand up to significant tension and ecological aspects. Unlike plastics, which might degrade gradually, light weight aluminum maintains its stability and performance under heats and pressures. In addition, while steel components can be heavier and vulnerable to rust, light weight aluminum stands up to rusting, boosting longevity. This combination of strength and toughness makes light weight aluminum casting a preferred selection for industries requiring reputable performance popular applications, such as automotive and aerospace industries.

Layout Versatility Comparison

The Future of Aluminum Spreading in Manufacturing

Exactly how will advancements in innovation form the future of aluminum casting in manufacturing? The integration of automation and fabricated intelligence is anticipated to revolutionize aluminum spreading procedures. These technologies can improve precision and performance, lowering waste and production expenses. Additionally, the appearance of 3D printing techniques enables quick prototyping and customized designs, making it possible for suppliers to react promptly to market demands.

Sustainability is additionally an essential focus, with technologies focused on minimizing power usage and lessening ecological effect. Techniques such as die spreading and financial investment casting are developing to incorporate recycled aluminum, advertising a round economy.

Furthermore, innovations in materials science may cause the growth of lighter, more powerful aluminum alloys that might broaden the applications of aluminum casting across different sectors. Generally, the future of aluminum casting in manufacturing will likely be identified by increased efficiency, adaptability, and sustainability, positioning it as an essential element of modern production strategies.

Often Asked Concerns

Just How Does Light Weight Aluminum Casting Impact Environmental Sustainability?

Light weight aluminum spreading positively impacts environmental sustainability by promoting recycling, minimizing energy consumption contrasted to various other metals, and decreasing waste. Its light-weight buildings additionally bring about decrease exhausts throughout transportation, sustaining greener methods in numerous industries.

What Are the Cost Effects of Light Weight Aluminum Casting?

Aluminum spreading typically entails higher initial costs because of material and handling expenses. Its durability and light-weight properties can yield long-lasting financial savings by reducing maintenance and transport prices, inevitably stabilizing the monetary implications for makers.

Can Aluminum Casting Be Recycled Successfully?

Aluminum casting can be recycled successfully, as the product preserves its homes throughout the reusing process. This get more info enables the manufacturing of premium parts while reducing waste and decreasing energy consumption connected with new light weight aluminum production.

What Security Measures Are Needed Throughout Aluminum Casting?

Precaution during light weight aluminum spreading include using personal protective tools like handwear covers and safety glasses, guaranteeing proper air flow, maintaining tools, and adhering to protocols for taking care of molten metal to stop burns, inhalation dangers, and other potential mishaps.

How Does Light Weight Aluminum Spreading Affect Product Design Flexibility?

Light weight aluminum casting improves product design adaptability by enabling light-weight frameworks and intricate forms. This technique enables designers to explore ingenious configurations, causing flexible applications throughout numerous sectors while maintaining strength and resilience in the end products.

Aluminum casting can be adjusted to various techniques, such as sand casting or die spreading, which widens its applicability throughout sectors. Once all procedures are total, the ended up aluminum parts are prepared for numerous applications, showcasing the versatility and efficiency of light weight aluminum spreading in manufacturing methods. As producers look for better efficiency and sustainability in production, ingenious advancements in light weight aluminum spreading technology have arised to satisfy these demands. Unlike plastic shot molding, which might need comprehensive tooling modifications for design modifications, aluminum casting can fit adjustments more conveniently during the production cycle. Developments in materials scientific research may lead to the advancement of lighter, more powerful aluminum alloys that could broaden the applications of light weight aluminum spreading throughout numerous industries.